Application of electric sweepers in the warehousing and logistics industry: Improving floor cleaning standards

Cleaning challenges in the warehousing and logistics industry

Warehousing and logistics centers usually face the need to clean large areas of hard floors (such as cement and epoxy floors). Traditional manual cleaning is inefficient and difficult to completely remove dust, debris and oil stains. In addition, high-frequency operating environments place extremely high demands on the durability, endurance and flexibility of equipment.

Industry adaptability of KINGDOM electric sweepers

As a cleaning equipment manufacturer with 15 years of industry experience, KINGDOM Cleaning Equipment (Jiangsu) Environmental Technology Co., Ltd.'s Walk Behind Power Floor Sweeper provides efficient solutions for the pain points of warehousing scenarios:

Efficient cleaning and energy-saving design

Adopting high-power motors and adjustable brush discs, it can easily deal with debris such as metal chips and packaging waste. The cleaning width covers more than 1m, and the efficiency of a single operation is increased by 3-5 times.

The lithium battery version (optional) supports 8-10 hours of battery life, meeting the continuous operation needs of large warehouses and conforming to environmental protection trends.

Durable and low maintenance cost

Relying on the company's modern production base (10,000+㎡) and advanced processes such as laser cutting and injection molding, the equipment body is made of impact-resistant materials to adapt to the high-frequency traffic environment of logistics forklifts.

The modular design facilitates the rapid replacement of brush plates and filters to reduce downtime.

Flexible customized services

As China's leading Walk Behind Power Floor Sweeper Manufacturers, KINGDOM supports customization according to customer scenarios (such as anti-static brush plates, silent mode, etc.), and provides full-chain support from drawing development to after-sales maintenance.

Actual application cases

KINGDOM's electric sweepers have served many international logistics centers and manufacturing warehouses. Customer feedback shows:

Cleaning time is shortened by 60% and labor costs are reduced;

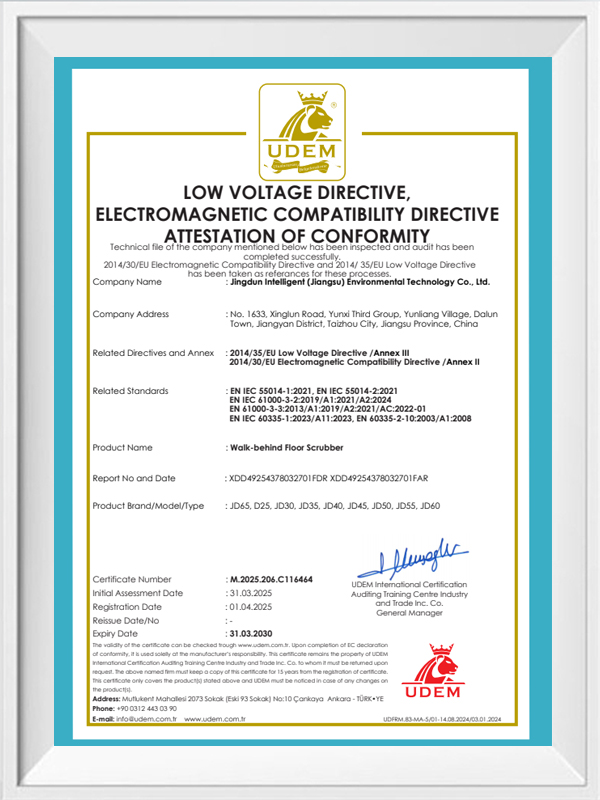

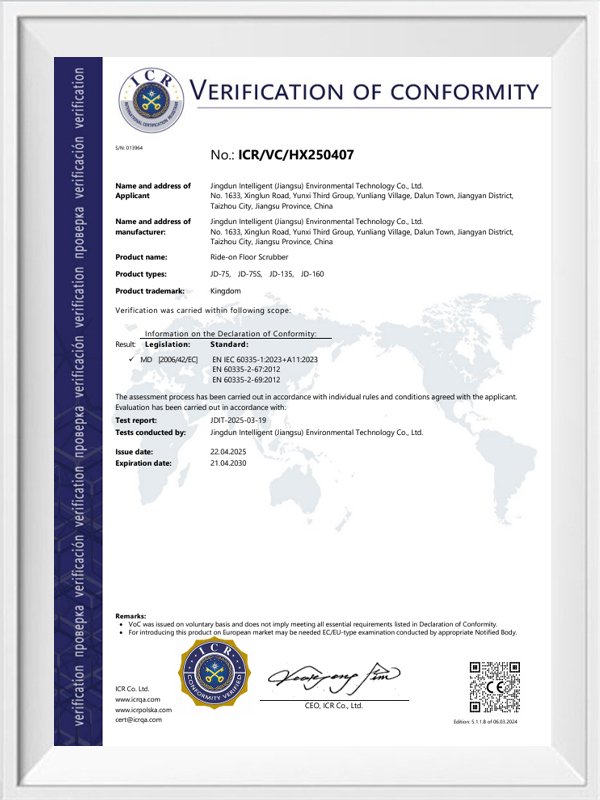

It meets the safety and noise standards of cleaning equipment in the European and American markets (such as CE certification).

Maintenance Guide: 5 Key Tips to Extend the Life of Walk Behind Power Floor Sweepers

As a world-renowned Walk Behind Power Floor Sweeper Manufacturers and Exporters, KINGDOM is well aware of the significant impact of equipment maintenance on operating costs and production efficiency. After tracking and studying hundreds of customer usage scenarios, we found that standardized maintenance can extend the service life of equipment by more than 40% and reduce maintenance costs by 30%. The following is our in-depth maintenance guide based on 15 years of industry experience:

1. Scientific maintenance of the brush system (directly affects the cleaning effect and equipment life)

Industry status analysis: In the warehousing and logistics industry, about 65% of equipment failures are caused by improper maintenance of the brush system. Our research shows that entanglements that are not cleaned in time will increase the motor load by 15-20%, significantly shortening the life of the equipment.

KINGDOM professional solution:

Daily maintenance: It is recommended to stop the machine for 5 minutes after every 2 hours of operation and use a special hook knife to remove brush entanglements (we provide professional cleaning tools with the equipment). Pay special attention to textile fibers, metal wires and other easy-to-entangle objects.

Periodic replacement: Develop a replacement plan based on the type of floor:

Epoxy floor: Replace every 400-500 hours

Rough cement floor: Replace every 200-300 hours

We provide a variety of brush discs such as wear-resistant and anti-static types

Adjustment tips: The brush disc should be kept at a height of 3-5mm from the ground and calibrated monthly with a special measuring tool (included in the KINGDOM standard maintenance package)

2. Deep maintenance of the filtration system (the core of determining suction stability)

Technical background: The efficiency of the modern sweeper filtration system directly affects the life of the motor. Test data shows that a clogged filter can increase the motor temperature by 20-25°C, significantly accelerating aging.

KINGDOM three-level filtration maintenance system:

Primary maintenance (daily):

Use compressed air to blow back (pressure ≤ 3 bar)

Check the integrity of the filter cotton

Intermediate maintenance (weekly):

Water-washable filters are soaked in 40℃ warm water (add special detergent)

HEPA filters are cleaned along the grain with a soft brush

Deep maintenance (monthly):

Use a filter material permeability tester to measure (standard value ≥ 85%)

Perform air tightness test

Innovative service: KINGDOM provides a filter health monitoring system (optional) to prompt replacement time in real time.

3. Precision maintenance of the power system (battery + transmission system)

Five golden rules for lithium battery maintenance:

Charging environment control: The charging efficiency is best in the temperature range of 5-35℃

SOC management: Maintain a power range of 20-80% (overcharging and over-discharging will lose 30% of the cycle life)

Balanced charging: Perform a complete 12-hour charge and discharge once a month

Winter storage: If the temperature is below -10℃, the battery needs to be removed and stored separately

Health detection: Use KINGDOM's special tester, and the internal resistance needs to be replaced if it exceeds 80mΩ

Main points for transmission system maintenance:

Gearbox: Replace special grease every 500 hours (ISO VG220 standard)

Belt drive: Tension meter detection maintains 8-10N/mm²

Chain drive: Use high-temperature chain oil for maintenance every month

4. Check the transmission system and tires

Chain/belt: Lubricate once every 3 months to prevent rust or breakage (KINGDOM equipment uses wear-resistant materials, but regular maintenance is still required).

Tires: Ensure sufficient air pressure (pneumatic tires) or no cracks (solid tires) to prevent the equipment from running off track.

Why is KINGDOM's maintenance solution more advantageous?

Original data support: Big data optimization solution based on 10,000+ devices

Global service network: 2-hour response, 48-hour on-site (major cities in China)

Customized service: Customized solution based on your ground type and operation time

Extended warranty plan: Customers who fully implement the maintenance plan can enjoy an additional 12 months warranty

English

English Español

Español عربى

عربى